Baseball in Montour County!

By: Lynn Reichen

Danville and Baseball

Walt Whitman fell for baseball in its first heyday saying “I see great things in baseball. It’s our game – the American game.”

Mention baseball and most fans will tell you Abner Doubleday invented the game. However, while Doubleday is credited with influencing baseball during the Civil War era, most historians believe Alexander Cartwright was the inventor of the modern game as we know it today. Whoever or whatever the origin of the game, whether from cricket, the colonial game of ‘Old Cat’ or the English game of Rounders, we Americans embraced it and made it our own. The Danville area was quick to join the ‘national pastime’ and local newspaper articles reporting on baseball can be found as far back as the 1850’s.

In 1865, the Philadelphia Athletics were hired by the residents of Danville for a fee of $700 to visit and assist in laying out a ball field below the town and to instruct the local team, the ‘Alerts” in the game as well. A team from Williamsport was also being organized and were invited to town to play. Almost 3,000 people became the first paying fans at a Danville baseball game. The crowd watched the Athletics defeat the Williamsport team by a score of 100 to 8 and Danville by a whopping 162 to 11.

One local game reported in the newspapers was played on the new grounds of the Danville B.B. Association, which lay between the canal and river at the lower end of Market Street. The Association had both fat and lean friends and these gentleman organized into two nines, the stout on the ‘Fats’ and the slim on the ‘Leans’. As time went on and as a ‘Fat’ player lost weight and became slimmer, he was transferred to the ‘Leans’ team and as a Lean player gained weight he was transferred to the ‘Fats’. These two teams played an exhibition game for the delight of their friends and to raise funds for the organization. The Fats were captained by Montgomery Gearhart of the D.L.&W. Company who, when attired for the game was expected to strike awe in the beholders! There was a headquarters tent for the wounded and only soft refreshments were allowed. The uniforms were gossamer shirts (sheer gauzy material) with large brass buttons and awning canvas pants. The ‘Leans’ lost the exhibition game and decided to retrieve their glory by challenging the ‘Fats’ to another game. Two weeks later the response to the challenge appeared in the newspaper: Danville, PA, Sept. 25, 1883. To the Capt. and Members of the Lean 9: Gentleman-We the Mastodons, accept your challenge given in the Record of the 20th inst. The game to be played on the Association grounds, Saturday Oct. 13. You play the same nine and under the same rules as our game of the 19th. signed A.M. Gearhart, Capt. The teams met on a Tuesday afternoon and the Fats were beaten in a 3 hour game. It was a game worth seeing, and also the last between these two teams.

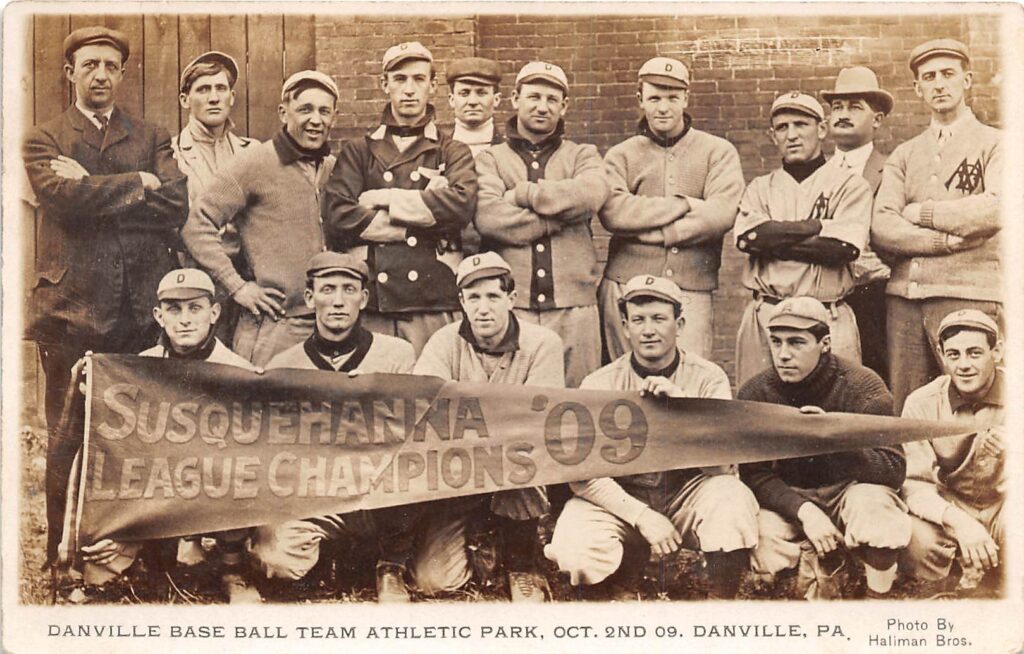

In 1909 a Danville baseball club became the Susquehanna League champions. In league games the team won twenty-two games, lost six and tied two. Of the thirty games, five were with a Bloomsburg team. The most famous Danville-Bloomsburg game occurred when Floyd Kroh (pronounce crow), alias George McCabe pitched for Danville. The fact that he was a professional player on furlough was not discovered until well into the game. When the Bloomsburg fans found out who he really was there was an uproar and the Danville team had a hard time leaving the field. For years later, Danville fans only had to call out ‘caw, caw’ to cause a fracas at any game in Bloomsburg.

Baseball diamonds were popping up all over the area, the fields were named the Ding Dongers, DeWitt Park, Rotary Field and the Fair Grounds. The field at the State Hospital was dedicated on May 30, 1927. The first night game under the lights was held in April 1931 on the parade grounds of the Danville Armory.

In 1910, the opening game of the season was between the Danville High School team and the Riverside High School Team. Danville won 12 to 5.

One of Danville’s most popular athletes who went into professional baseball was Robert John Rhawn. His professional debut in 1947 was in the Cardinal chain and he was a member of the standout New Cumberland nine during part of his four years in the military. He was sold by the Cards to the New York Giants and was a top third baseman in the league. Bobby died in Danville in 1984 after playing with the NY Giants and the Chicago White Sox.

Through the recent years many teams and leagues for all ages and skills were sponsored by social clubs, fire companies and business such as the Moose, Elks, the Washies and Continental, McWilliams and Merck. In the 1930s the American Legion developed a program for young men and the YMCA Junior League Association became part of the Little League organized in Williamsport. The citizens of Danville and area have played and loved the game of baseball for over 150 years, and every spring I wait for those two words, ‘Play Ball!’

Sources: ‘Always a Baseball Town’ Danville News IHF souvenir edition 2006

The official IHF 2006 program

My Danville, by Arthur T. Foulke 1969